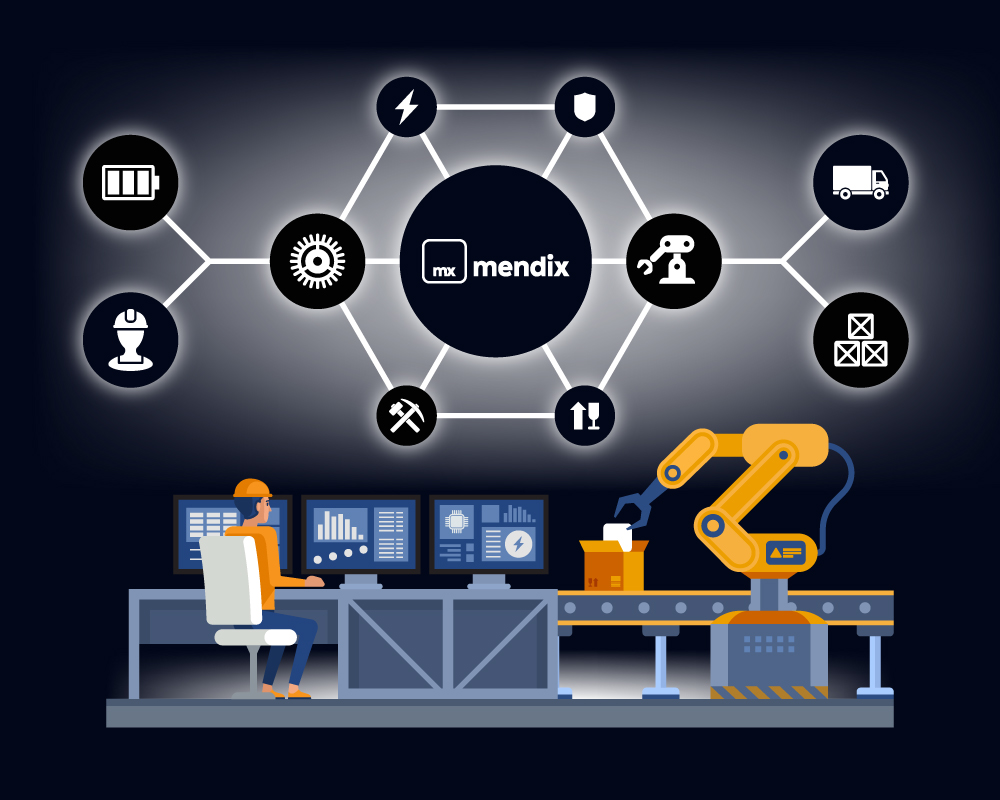

Mendix Manufacturing Operations Management

This case study highlights how a global manufacturing enterprise modernized its manufacturing operations using a Mendix low-code platform, enabling centralized operations, reduced manual effort, and improved visibility across multiple plants.